CLICK HERE TO BUY NOW FOR NON-ATTA FUEL TANKS.

Note: If you have a ATTA made fuel tank, please call us at 1-800-773-3047 with your Model Number and Serial Number to receive a lower price.

HOW THE FREEDOM FILL AUXILIARY SYSTEM WORK.

When the system is turned on, the Freedom Fill Controller box will sense when the factory tank is approximately at a half a tank, the controller box will then turn the auxiliary in-line pump on, filling the factory tank to approximately three-quarters of a tank. The light on the switch will turn on allowing you to know when the system is transferring fuel. When the factory tank reaches approximately three-quarters of a tank, the pump will then turn off. When the auxiliary tank is empty, the system will not turn on. If the factory tank goes below approximate one-half of a tank, you know the auxiliary tank is empty. When the switch is in the off position, the auxiliary gauge and computer will be off, and will not transfer fuel from the auxiliary tank to the factory tank.

When the truck or the system first turns on, the pump &light will turn on for approx 5 seconds, then turn off. If the factory tank needs fuel it will then turn back on and begin to transfer fuel. If the factory tank is above approx ½ a tank, the system will remain off until the factory tank reaches the appropriate level of approx ½ a tank. If the truck or Freedom Fill System is shut off during fuel transfer, it will not turn back on until the factory tank reaches approx half a tank.

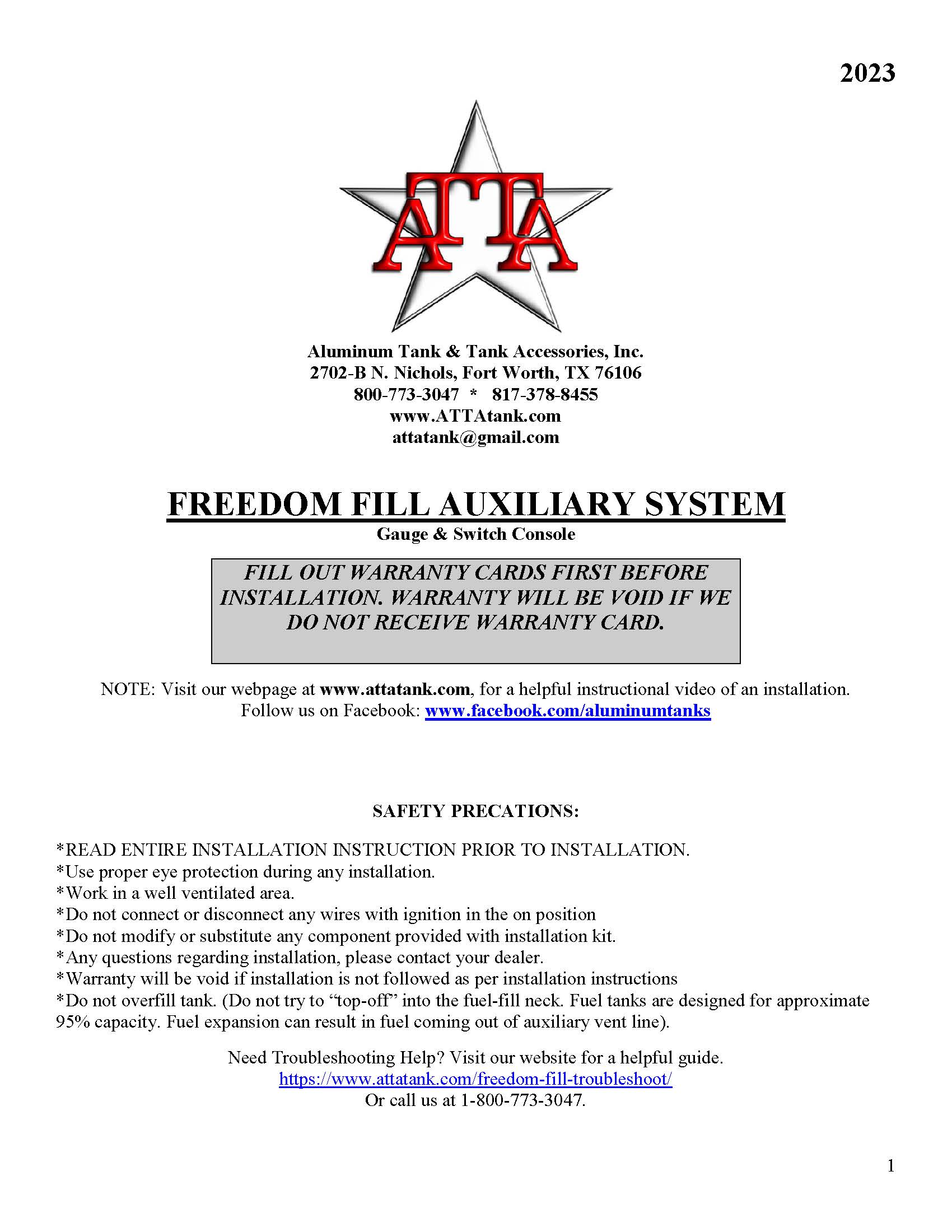

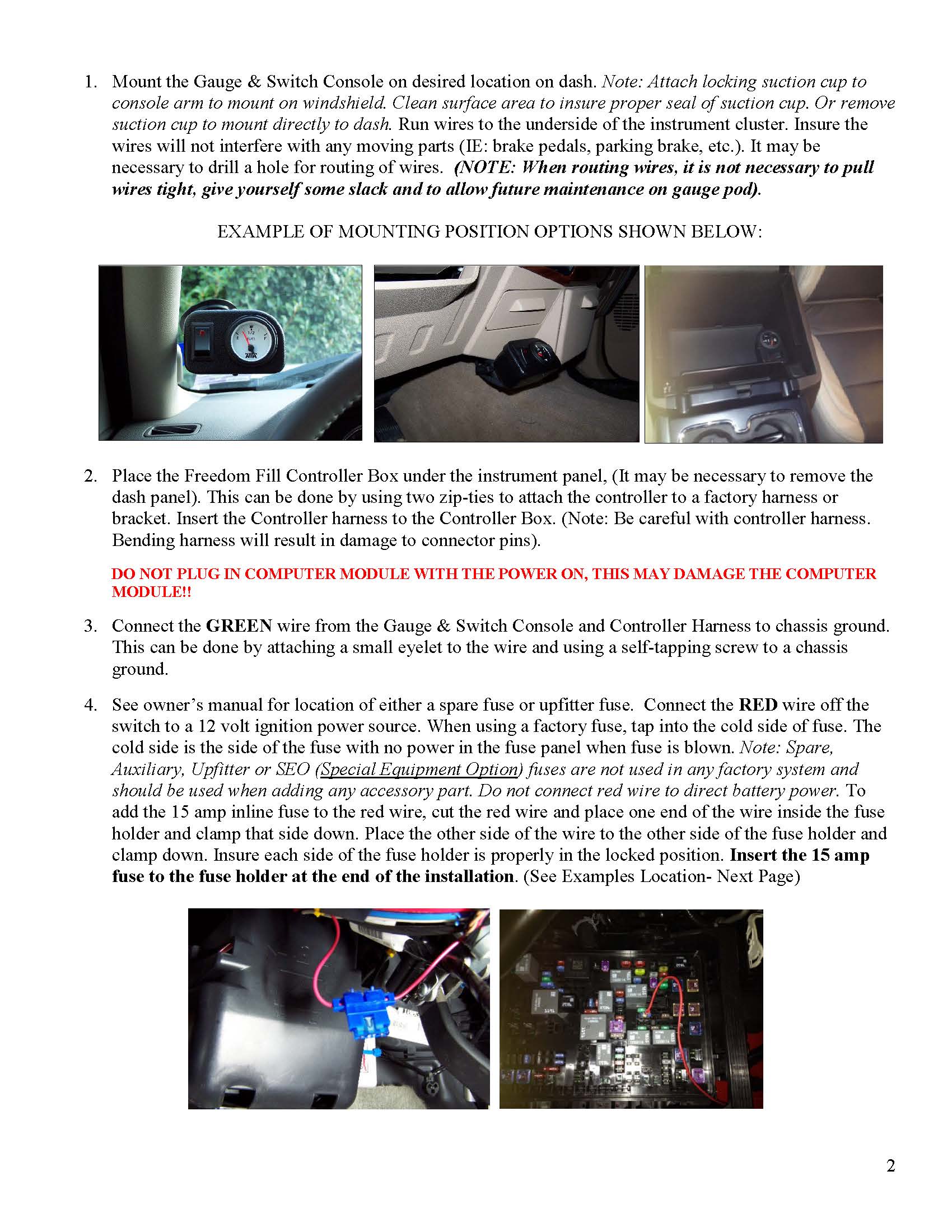

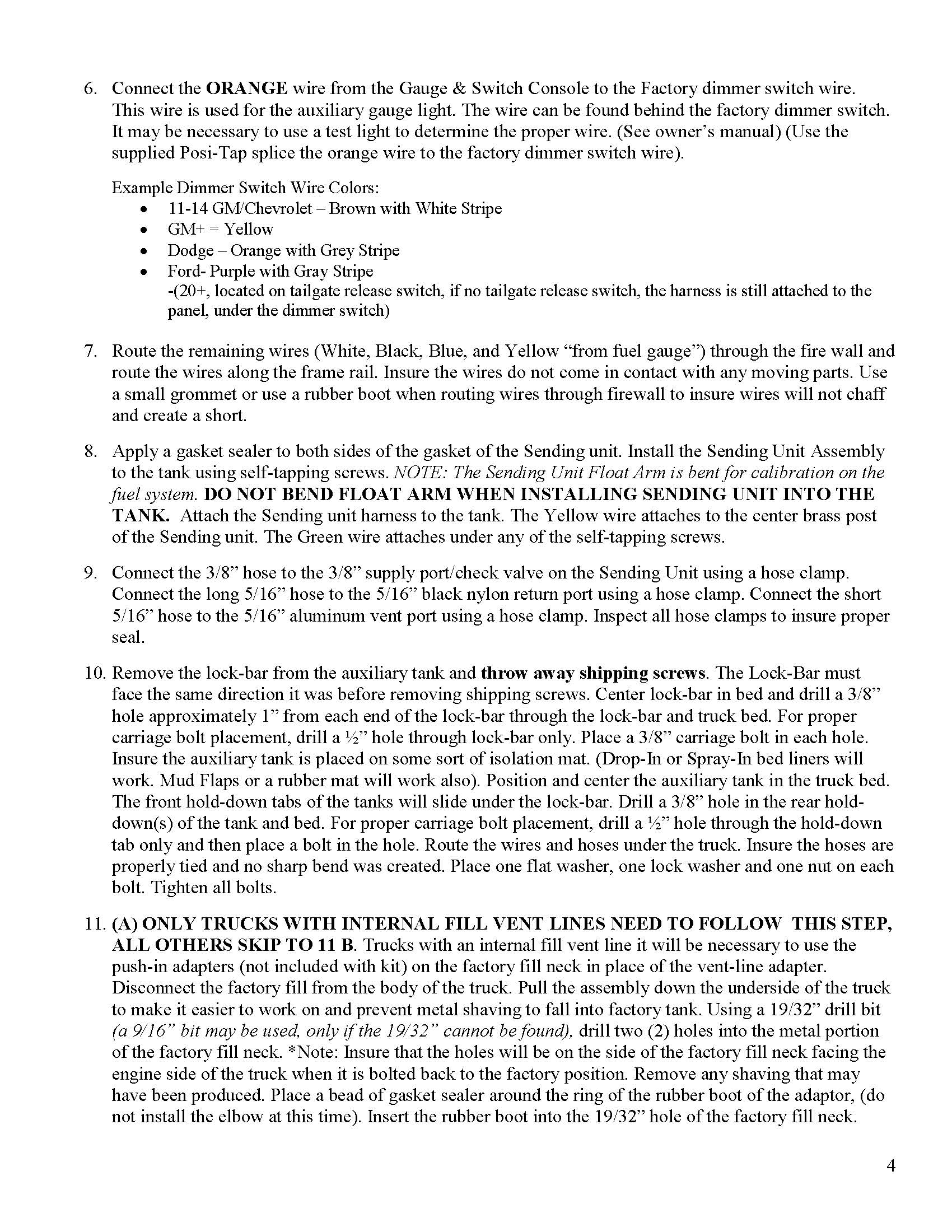

FREEDOM FILL AUXILIARY SYSTEM INSTALLATION INSTRUCTIONS.